Yd8-200 Premade Hnab Ntim Tshuab nrog Tus Nqi Zoo

Txheej txheem cej luam

Txheej txheem cej luamLub hnab muab lub tshuab ntim khoom hloov pauv ntawm phau ntawv ntim hom, uas pab cov lag luam loj, cov lag luam me thiab nruab nrab ncav cuag ntim automation, cov cuab yeej siv tshuab yuav cia li nqa lub hnab, luam tawm hnub, qhib lub hnab, mus rau lub metering ntaus ntawv teeb liab ntsuas thiab blanking, sealing, tso zis. Kev xaiv tseem ceeb rau kev ntsuas cov khoom filling tshuab ua haujlwm platform, qhov hnyav, nplai, khoom siv hoist, vibrating feeder, tiav cov khoom thauj hoisting tshuab, hlau nrhiav tshuab, thiab lwm yam.

Nws txais Nyiv cov thev naus laus zis tshiab, nyob rau hauv tag nrho cov kev tswj hwm ntawm PLC + POD, txais yuav cov qauv siv tshuab, kev ua haujlwm maj mam hloov cov kev ua haujlwm ntawm cov qauv pneumatic, tsim kom muaj kev xav tau ntau dua ntawm kev ua cov thev naus laus zis, kev ua haujlwm yooj yim, ruaj khov, txij nkawm, yooj yim los ntxuav, zoo nkauj tsos.

A. Kev hloov ceev ceev ntawm cov khoom tshwj xeeb ntawm lub hnab, lub hnab dav tuaj yeem hloov kho los ntawm ib lub pob.

B. Ib leeg ncej thiab CAM tsim: packing ceev ceev; ruaj khov ua haujlwm ntau dua; txij nkawm yooj yim dua thiab txo qis tus nqi.

C. Modular cua sov, tswj qhov kub thiab txias dua, cua sov ua txhaum muaj lub tswb nrov.

D. Advanced tsim lub tswv yim, txo cov khoom poob, xyuas kom ruaj khov ntawm cov cuab yeej ua haujlwm, txuas lub neej ua haujlwm ntawm cov khoom siv.

E. Kev ua haujlwm yooj yim thiab yooj yim, siv lub siab tshaj PLC + POD (kov screen) hluav taws xob tswj qhov system thiab txiv neej-tshuab interface.

F. Tshuab muaj ntau yam ntim, nws muaj peev xwm ntim tau: kua, muab tshuaj txhuam, granule, hmoov, khoom ntau yam bagging khoom xwb. Raws li cov khoom sib txawv nrog cov khoom sib txawv metering.

G. Tshuab siv preformed hnab & ntim tsim yog zoo meej & zoo sealing zoo los txhim kho qhov zoo thiab qib ntawm cov khoom.Parameter ntawm tshuab

| Qauv | ZP8-200/ZP8-260/ZP8-320 |

| Cov khoom ntim | 3-sab, plaub ntug-sealing hnab, tus kheej-reliance hnab, handbag, spout hnab, zipper hnab, compound hnab, thiab lwm yam |

| qhov loj | W: 50-200/100-250/180-300 |

| Filling ntau yam | 10-1000g / 20-2000g / 30-2500g |

| Packing ceev | 10-60bag / min (ceev yog txiav txim los ntawm cov khoom ntim ntau) |

| Nruab nrab precision | ≤ ± 1 |

| Tag nrho lub zog | 2.5 KW TSI |

| Qhov ntev | 1900mm X 1570mm X 1700mm / 2000mm X 1570mm X 1700mm / 2100mm X 1630mm X 1700mm |

| Kev khiav haujlwm | muab lub hnab → coding → qhib → filling 1 → filling 2 → auxiliary → exhaust → heat sealing → .forming and output product |

| Muaj feem xyuam | 1. Cov khoom thaiv: taum curd ncuav mog qab zib, ntses, qe, khoom qab zib, liab jujube, cereal, chocolate, biscuit, txiv laum huab xeeb, thiab lwm yam |

| 2.Granular hom: siv lead ua monosodium glutamate, granular tshuaj, tshuaj ntsiav, noob, tshuaj, qab zib, nqaij qaib essence, melon noob, txiv ntseej, tshuaj tua kab, chiv | |

| 3.Powder hom: mis hmoov, qabzib, monosodium glutamate, seasoning, ntxuav hmoov, tshuaj cov ntaub ntawv, nplua dawb qab zib, tshuaj tua kab, chiv, thiab lwm yam | |

| 4.Liquid/paste type: detergent, rice wine, soy sauce, rice vinegar, fruit juice, haus, txiv lws suav, txiv laum huab xeeb, jam, kua ntses, taum paste | |

| 5.Class of pickles, pickled cabbage, kimchi, pickled cabbage, radish, thiab lwm yam | |

| 6.Lwm lub hnab ntim khoom | |

| Main txheem qhov chaw | 1. Code tshuab luam ntawv 2. PLC tswj qhov system 3.Bag qhib ntaus ntawv 4. Vibration device 5.Cylinder 6. Electromagnetic valve 7. Temperature controller 8.Vacuum pump 9. Inverter 10. Output system |

Tshuab cov qauv

1, ZP8-200: Siv lub hnab dav: 50-200mm

2, ZP8-260: Siv lub hnab dav: 100-250mm

3.ZP8-320: Siv lub hnab dav: 180-300mm

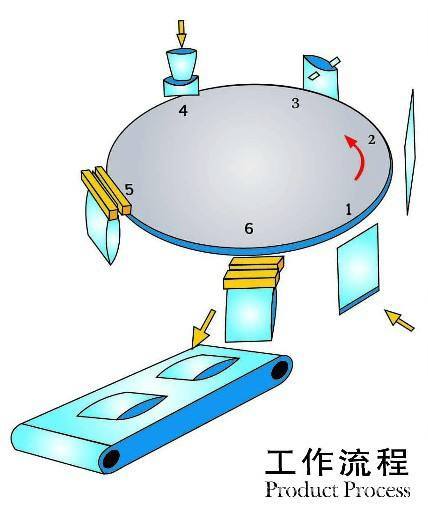

Kev khiav haujlwm

Cov qauv

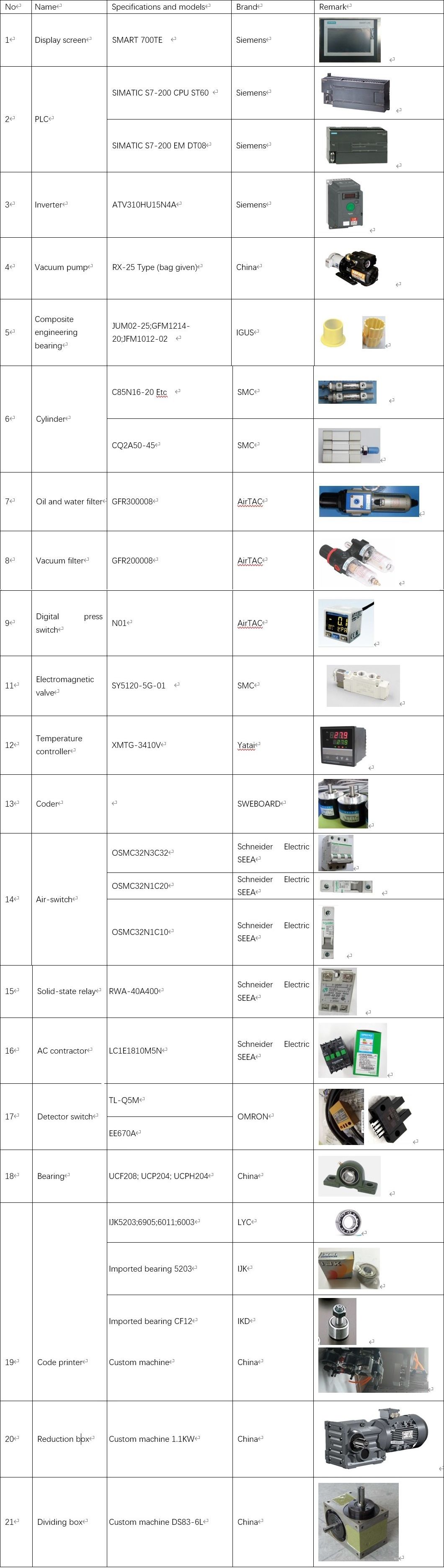

Configuration list

Ntxiv qhov chaw ua haujlwm

Raws li lub hnab specifications thiab daim ntawv, ua ke nrog ntau lawm cov khoom, coj mus xaiv cov nram qab no nta ntxiv siv nyob rau hauv lub tshuab:

1. 5 chaw nres tsheb cov khoom siv (khoom siv lub tog raj kheej, haum rau kev siv cov kua dej tsis siab thiab ob zaug raw khoom ntxiv)

2. 6 chaw nres tsheb (cantilever chims ntawm cov khoom)

3. Cov pa tawm (tseem siv tau los tshem tawm cov khoom siv roj)

4. Nyob rau hauv vibration (tseem hu ua lub hnab vibrate, muaj feem xyuam rau cov khoom thaiv lossis cov khoom loj)

5. Qib hnab (muaj feem xyuam rau lub hnab zipper thiab hnab mos)

6. Qhib lub hnab zipper (muaj feem xyuam rau lub hnab zipper)

7. Kaw zipper (muaj feem xyuam rau lub hnab zipper)

8. Lub hnab qhib (muaj feem xyuam rau lub hnab zipper thiab tsis yooj yim rau qhib lub hnab)

9. Hopper kev co (muaj feem xyuam rau cov khoom siv uas tsis tshua muaj kua)

10. Sweep plua plav thiab hmoov av (muaj feem xyuam rau hmoov)

Cov khoom siv sib txuas

1. Lub elevator:

Z hoist, baffle hoist, hoist ntawm loj poob lub kaum sab xis, ib lub thoob of elevator, ntsia hlau hoist, tais hom hoist, thiab lwm yam

2. Lub koob tshuaj thiab lub tshuab filling:

Combination hu ua contraction, khob, ntsia hlau, filling tshuab, pickles, suav naj npawb tshuab, thiab lwm yam

3. Lub platform ua haujlwm

4. Cov khoom tiav conveyor

Associated adopts (ib txwm)

2. hmoov: party + ntsia hlau hoist + ntsia hlau hais

3. grain: party + ntsia hlau hoist + ntsia hlau hais (me me)

Lub party + + platform + ua ke hoist hais (loj particle)

4. qaub pickled cabbage: party + hoist + + pickles tshuab filling tshuab (kua siv, xaiv tau)

Lub party + + platform + ua ke raws li hoist + filling tshuab (kua siv, tuaj yeem xaiv)

5. pickle: party + pickles tshuab + nce qib + filling tshuab, filling tshuab (kua siv, tuaj yeem xaiv)

Lub khob khob + + kev cog lus hoisting tshuab, filling tshuab thiab filling tshuab (kua siv, tuaj yeem xaiv)

6. pickles: party + + + platform + electronic scale hoist filling tshuab

Lub party + lub tais hom hoisting tshuab, filling tshuab (semi-automatic, khoom noj khoom haus)

(daim ntawv no ua tiav rau ob hom khoom sib xyaw, ob qho kev pub mis, piv txwv li: Qing Shui Sun si, pickled peppers lotus root zone, etc.)

7. kua, muab tshuaj txhuam, party + filling tshuab

8. lub hnab ntim khoom: tus tswv tsev + damper winding tshuab

Factory duab